ORGANIC NANOCARBO™ — 5‑fraction booster from walnut shells for vegan leather, cellulose, and PU materials

the end of the animal-leather argument

— easily integrates into all plant-based formulas

of vegan bio-leather manufacturers without altering the production process

We are a small family-run company from Kyiv, Ukraine, specializing in creating the eco-friendly plant-based material ORGANIC NANOCARBO™, made from walnut shells for sustainable sandblasting, surface restoration, polishing, and decorative design — proving the versatility of nature in modern industry.

Beyond these uses, we also apply it in vegan and plant-based leathers.

Beyond these uses, we also apply it in vegan and plant-based leathers.

- Epicarp (outer layer)

- Mesocarp (middle layer)

- Endocarp (inner layer)

- Seed membrane

- Walnut kernel fragments

By incorporating this into the production of vegan leather, manufacturers create a product with technical characteristics indistinguishable from traditional animal leather.

Ultra-fine plant-based powder: 0.001–0.1 mm (1–100 μm) for seamless blending and deep integration into vegan leather compositions.

- Epicarp (outer layer)

- Mesocarp (middle layer)

- Endocarp (inner layer)

- Seed membrane

- Walnut kernel fragments

By incorporating this into the production of vegan leather, manufacturers create a product with technical characteristics indistinguishable from traditional animal leather.

Ultra-fine plant-based powder: 0.001–0.1 mm (1–100 μm) for seamless blending and deep integration into vegan leather compositions.

Our material is the only plant-based raw material proven to function in bioreactors for producing bacterial or bio-modified cellulose, enabling vegan leather to reach the performance standards required for FIFA-level applications. The presence of these natural components is the guarantee of success: walnut shell contains up to 60% cellulose and up to 30% lignin — the key factors behind its intrinsic strength and durability. The remaining fraction is made up of extractives and mineral ash, which further reinforce the stability of the structure.

Average chemical composition of dried walnut shell:

- α-Cellulose: 25–30%

- Hemicellulose: 20–25%

- Lignin: 30–35%

- Extractives (phenolics, tannins, fats, sugars): 5–8%

- Ash (minerals such as Ca, K, Mg, Si, Fe): 1–2%

The Role of Lignin in ORGANIC NANOCARBO™

Unlike in paper pulp or bioethanol production, where lignin is often considered an impurity, in advanced vegan leather and bio-composites lignin is a natural advantage. With 20–30% lignin content, walnut shell powder provides a crystalline framework that:

· strengthens tensile performance and durability,

· increases resistance to cracking and moisture,

· ensures long-term stability without synthetic nanofillers.

This natural balance of cellulose, hemicellulose, and lignin makes ORGANIC NANOCARBO™ uniquely suitable for high-performance materials, including vegan leather that can meet FIFA-level standards.

The Advantage of 60% Cellulose in ORGANIC NANOCARBO™

With a naturally high cellulose content of around 60%, walnut shell powder provides a stable growth medium for bacterial and modified cellulose. This crystalline fraction not only supports film formation and fiber reinforcement but also ensures efficient bonding with pigments. As a result, ORGANIC NANOCARBO™ enables scalable, high-performance vegan leather production without the need for synthetic additives.

🛡️ BIOLOGICAL STABILITY AND SHELF LIFE

ORGANIC NANOCARBO™ resists mold and microbial degradation during use, ensuring long-term stability and performance.

At the same time, the material is fully plant-based and can be responsibly disposed of through industrial composting programs.

Durable in use. Sustainable in the end.

• Fully dry — contains no moisture and no nutrient medium for microorganisms

• Requires no special storage conditions

• Can be stored for years without any visible changes

• Shelf life: unlimited

Part 2⬇️

Technical Parameters & Biological Research

Plant-Based Compatibility

Part 1

⬇️

ORGANIC NANOCARBO™ It blends perfectly with other plant-based components used in vegan leather formulations and biocomposites.

The multi-fractional structure is compatible with all existing types of vegan leather.

to plant-based formulations enhances vegan leather to premium leather goods standards.

Vegan leather producers easily add the booster to current production — no equipment changes or additional costs.

Thanks to its unique formula, it can truly help stop the suffering of defenseless animals!

- In polyurethane and water-borne PU systems– added as a filler/booster, improving mechanical properties without the need to change the process.

- In bio-PU and plant-based polyols– enhances flexibility and color fastness while preserving the “bio-based” positioning of the final product.

- In natural binders (lignin, starch, tannins, proteins)– acts as a source of microcrystalline cellulose and a structural modifier, enabling the production of fully-bio materials without synthetic components.

- In matrices based on bacterial and nanocellulose– integrates organically into gel-like matrices, increasing strength and wear resistance without loss of elasticity.

- In fibre-based and agro-waste substrates (Piñatex, Vegea-type analogues, etc.)–distributes uniformly in nonwovens, creating a stronger and more stable base before binder application.

Here you can view data on the reduction dynamics of animal usage in leather production and the list of animals replaced by our material.

⬇️

"Animal Use Reduction by Material Type"When applied in the production of bacterially modified cellulose, the result is leather that meets FIFA standards.

Here you can view the list of compatible materials and examples of typical formulations.

- Where ORGANIC NANOCARBO™ works for you:1. In polyurethane and water-borne PU systems – added as a filler/booster, improving mechanical properties without the need to change the process.2. In bio-PU and plant-based polyols – enhances flexibility and color fastness while preserving the “bio-based” positioning of the final product. 3. In natural binders (lignin, starch, tannins, proteins) – acts as a source of microcrystalline cellulose and a structural modifier, enabling the production of fully-bio materials without synthetic components.4. In matrices based on bacterial and nanocellulose – integrates organically into gel-like matrices, increasing strength and wear resistance without loss of elasticity.5. In fibre-based and agro-waste substrates (Piñatex, Vegea-type analogues, etc.) – distributes uniformly in nonwovens, creating a stronger and more stable base before binder application.

- Cellulose from walnut shells — the pathway to high-strength materials, while maintaining or even surpassing the mechanical performance demanded in FIFA-level equipment.

- Sample Bio-Reactor Pathways — 100% ORGANIC NANOCARBO™ Integration for FIFA-Grade Vegan Leather• No changes to production lines — ORGANIC NANOCARBO™ is compatible with existing lamination, calendering and coating processes. • Universality — a single material suitable for PU dispersions, natural adhesive systems, and nanocellulose matrices. • Fractional structure — optimal particle distribution (10–100 µm) ensures rapid and uniform mixing, reducing time and risks at the experimental stage. • Backed by research — European projects (Horizon Europe, PUZZLE MATERIALS) and publications in biocomposites indicate the potential of walnut shell as a sustainable and effective component. • Ethical value — PETA-certified; application reduces the use of animal leather by 80% (according to our calculations available on the website).

ANIMAL USE REDUCTION POTENTIAL WITH ORGANIC NANOCARBO™: SCIENTIFIC EVIDENCE, VISUAL PROOF

From fashion to accessories, from footwear to upholstery. From Premium Leather to FIFA Standard — our plant-based material helps manufacturers move away from animal-derived sources without compromising quality.

You can see it: our additive increases structural compatibility, pigmentation strength, and long-term durability — which leads to significantly higher substitution rates compared to standard plant leathers.

⬇️ Explore the comparison. Use the evidence. Make the switch.

Support for Innovators in Vegan Leather:

ORGANIC NANOCARBO™ — The №1 Plant-Based Color Enhancer for Superior Pigmentation and Color Properties in Vegan Leather Production

🎨 COLOR PROPERTIES AND THERMAL ACTIVATION

ORGANIC NANOCARBO™ influences the final color of vegan leather through built-in natural pigment components located in the anatomical layers of walnut shells. This enables a stable, natural palette — from light wood-like tones to deep browns.

🟤 1. STANDARD PROCESSING (NO BOILING)

When the powder is added to the base plant compound without additional thermal activation:

- Light, wood-like, and slightly nutty tones appear

- Color is distributed evenly throughout the matrix

- Natural appearance and stability are preserved — even after embossing and finishing

- No fading effect over time

This mode is ideal for formulations where dark tones are not required, e.g., for materials with “eco” or “raw” styling.

🌑 2. THERMAL ACTIVATION – COLOR ENHANCEMENT

When heated or boiled within the composition, natural pigment release is triggered — primarily from the endocarp and kernel membranes, which contain:

🧪 Iodine-based and phenolic compounds:

- Organically bound iodine in membrane structures reacts with phenolic groups (such as tannins)

- Upon heating, these compounds oxidize and polymerize, intensifying the dark tones

- This results in a deep, stable, and noble brown shade — unachievable with synthetic dyes

In addition, iodine and tannin compounds act as natural color fixatives, stabilizing the color throughout the mass and preventing washout or UV fading.

🎛 COLOR CONTROL BY MANUFACTURER

The manufacturer can choose the processing mode:

- Without thermal activation → light, natural tones

- With activation → rich, dark, premium shades

In both cases, the following are preserved:

- Increased tear resistance

- Pigment stability

- Full compatibility with standard manufacturing processes

📌 BENEFITS FOR MANUFACTURERS

- Deep, natural color — without dyes

- Tunable color depth within the same product

- Stable coloration — after drying, embossing, and finishing

- Easy integration — only temperature adjustment required

Vegan Materials Comparison

and a Little About the PUZZLE MATERIALS Project on CORDIS (Official European Commission Database) and Related Scientific Publications

PUZZLE MATERIALS — Sustainable Material Solutions from Walnut ShellsOverview:

PUZZLE MATERIALS is a Horizon Europe research project focused on transforming walnut shells into high-performance, eco-friendly materials.

The project develops innovative processes to dissolve the unique 3D puzzle-cell structure of the shell, recover lignin, and integrate it into biopolymers. Applications include NUTleather (a plant-based leather alternative) and NUTplastic (biodegradable plastic with improved strength).

Key Innovations:

- Utilization of walnut shell’s naturally interlocked cell structure for mechanical strength.

- Recovery and valorization of lignin and cellulose.

- Development of sustainable composites with high durability and flexibility.

- Potential applications in fashion, automotive, and packaging industries.

Links:

- CORDIS Project Page: https://cordis.europa.eu/project/id/

Coordinator — University of Natural Resources and Life Sciences (BOKU), Vienna: https://www.boku.ac.at

SCIENTIFIC EVIDENCE OF WALNUT SHELL STRENGTH AND ITS POTENTIAL IN COMPOSITES

Based on research by SEBASTIAN ANTREICH, NANNAN XIAO, JESSICA C. HUSS, NILS HORBELT, MICHAELA EDER, RICHARD WEINKAMER, and NOTBURGA GIERLINGER

1. Antreich et al., 2019 – The Puzzle of the Walnut Shell: A Novel Cell Type with Interlocked Packing

Unique polylobate sclereids form a 3D structure that prevents crack propagation under load. The tensile strength is higher than that of pine cone scales.

Publication: https://www.ncbi.nlm.nih.gov/pmc/articles

Author: https://www.researchgate.net/profile/Sebastian-Antreich

2. Antreich et al., 2022 – The walnut shell network: 3D visualisation of symplastic connections

Detailed 3D visualisation of walnut shell cell architecture, showing the interconnected network of cells and its influence on mechanical strength.

Publication: https://link.springer.com/article/10.1007/s00425-022-03960-w

Author: https://www.researchgate.net/profile/Sebastian-Antreich

3. Antreich et al., 2024 – A belt for the cell: Cellulosic wall thickenings and their role in morphogenesis of the 3D puzzle cells

Microscopic studies showed that cellulose wall thickenings guide growth and shape formation of the 3D puzzle cells.

Publication: https://doi.org/10.1093/jxb/erab197

Author: https://www.researchgate.net/profile/Sebastian-Antreich

4. Xiao et al., 2020 – From the Soft to the Hard: Changes in Microchemistry of the Walnut Shell during Development

Short description: During maturation, walnut shell increases in lignin and cellulose content, enhancing protective and mechanical properties.

Publication: (alt: Frontiers full text — https://www.frontiersin.org/journals/plant-science/;)

Author: https://www.researchgate.net/profile/Nannan-Xiao

5. Xiao, 2021 – Nutshell structures for high strength and energy absorption

The lignin–carbohydrate framework forms thick-walled puzzle cells capable of absorbing substantial mechanical loads.

Publication: https://pmc.ncbi.nlm.nih.gov/articles/PMC8355673/

Author: https://www.researchgate.net/profile/Nannan-Xiao

Comparison of Shore A/D and Mohs hardness of materials used in vegan leather production

https://organic-nanocarbo.com/[Technical Parameters]

- In polyurethane and water-borne PU systems– added as a filler/booster, improving mechanical properties without the need to change the process.

- In bio-PU and plant-based polyols– enhances flexibility and color fastness while preserving the “bio-based” positioning of the final product.

- In natural binders (lignin, starch, tannins, proteins)– acts as a source of microcrystalline cellulose and a structural modifier, enabling the production of fully-bio materials without synthetic components.

- In matrices based on bacterial and nanocellulose– integrates organically into gel-like matrices, increasing strength and wear resistance without loss of elasticity.

- In fibre-based and agro-waste substrates (Piñatex, Vegea-type analogues, etc.)–distributes uniformly in nonwovens, creating a stronger and more stable base before binder application.

Export & Delivery Terms:

- Export-ready ORGANIC NANOCARBO in 15kg. (for large fractions 25 kg.) lined paper bags

- whether in 300 kg. (for large fractions 400 kg.) BIG BAGS

- Free lab-scale samples for initial testing

As a B2B exporter, ORGANIC NANOCARBO™ delivers materials under internationally recognized Incoterms 2020.

We offer flexible and transparent delivery options to suit your production and logistics needs:

- Export-ready ORGANIC NANOCARBO in 15kg. (for large fractions 25 kg.) lined paper bags

- whether in 300 kg. (for large fractions 400 kg.) BIG BAGS

- Free lab-scale samples for initial testing

As a B2B exporter, ORGANIC NANOCARBO™ delivers materials under internationally recognized Incoterms 2020.

We offer flexible and transparent delivery options to suit your production and logistics needs:

CPT (Carriage Paid To) – We organize and pay for delivery to the agreed destination (e.g., Warsaw, Berlin, Milan), while transfer of risk occurs once the goods are handed over to the first carrier.

DAP (Delivered At Place) – We deliver the goods directly to your facility; customs clearance in the destination country remains the responsibility of the buyer.

FCA (Free Carrier) – For customers with their own logistics partners, we can hand over the goods at our designated point in Kyiv.

Each shipment includes proper documentation and eco-conscious packaging to ensure a smooth and sustainable delivery process.

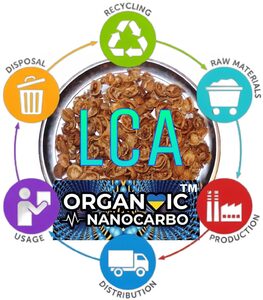

♻️ Our Vision: Circular Process & Ultra-Low Carbon Footprint

At the core of our philosophy is a commitment to a truly sustainable future. We believe that innovation should arise not only from advanced technologies, but from deep respect for nature, resources, and life on Earth.

Our plant-based booster powder, ORGANIC NANOCARBO™, is developed in line with the principles of a circular economy. We use only by-products from walnut shell processing — natural raw material that would otherwise become waste. This approach not only reduces environmental pressure, but also gives new value to overlooked plant resources.

We do not use water, chemical additives, or thermal energy. Our logistics follow a low-emission model, with a preference for rail transport over carbon-intensive methods. Our production process is designed for carbon-conscious operation, minimizing CO₂ emissions at every stage and avoiding environmental harm.

🌀 We strive for full circularity, where reuse and regeneration are not exceptions, but the standard.

FAQ

ORGANIC NANOCARBO™

Key Answers for the Vegan Leather Industry

FAQ

ORGANIC NANOCARBO™

Key Answers for the Vegan Leather Industry

Answers to 7 key questions from manufacturers about performance, integration, and how this material changes the market forever.

❓ What makes ORGANIC NANOCARBO™ a paradigm shift rather than just an incremental improvement

❓ What makes ORGANIC NANOCARBO™ a paradigm shift rather than just an incremental improvement

❓ How does it eliminate the last argument for animal leather (quality and look)

❓ How does it eliminate the last argument for animal leather (quality and look)

❓How smoothly does it integrate into existing production

❓How smoothly does it integrate into existing production

❓ Which performance metrics are critical — and how does ORGANIC NANOCARBO™ enhance them

❓ Which performance metrics are critical — and how does ORGANIC NANOCARBO™ enhance them

❓ What industry-level change does adoption unlock

❓ What industry-level change does adoption unlock

❓What about reliability, storage, and lifecycle considerations

❓What about reliability, storage, and lifecycle considerations

❓ How does adoption contribute to reducing animal slaughter

❓ How does adoption contribute to reducing animal slaughter

ABOUT US

We are a small family-run company from Kyiv, Ukraine, specializing in creating the eco-friendly plant-based material ORGANIC NANOCARBO™, made from walnut shells for sustainable sandblasting, surface restoration, polishing, and decorative design — proving the versatility of nature in modern industry.

Beyond these uses, we also apply it in vegan and plant-based leathers.

As a result of biological research, we developed a unique five-fraction formula designed specifically for plant-based leathers and biocomposites, built on the natural strength of walnut shells.

It is the first reinforcing additive material comparable to natural leather in durability and color stability — already used in premium vegan bio-leathers, bacterial cellulose, and PU materials — ensuring compliance with FIFA performance standards.

The unique properties of our material represent a true breakthrough and paradigm shift in the vegan bio-leather industry.

Our mission is to provide environmentally conscious manufacturers with an innovative, high-quality natural additive derived from an agricultural by-product.

EVERY M² OF ORGANIC NANOCARBO™ MEANS LESS SUFFERING FOR DEFENSELESS ANIMALS, LESS CO₂ THANKS TO A CLOSED AND ZERO-WASTE PRODUCTION CYCLE, AND MORE HOPE FOR THE PLANET.

We are a small family-run company from Kyiv, Ukraine, specializing in creating the eco-friendly plant-based material ORGANIC NANOCARBO™, made from walnut shells for sustainable sandblasting, surface restoration, polishing, and decorative design — proving the versatility of nature in modern industry.

Beyond these uses, we also apply it in vegan and plant-based leathers.

As a result of biological research, we developed a unique five-fraction formula designed specifically for plant-based leathers and biocomposites, built on the natural strength of walnut shells.

It is the first reinforcing additive material comparable to natural leather in durability and color stability — already used in premium vegan bio-leathers, bacterial cellulose, and PU materials — ensuring compliance with FIFA performance standards.

The unique properties of our material represent a true breakthrough and paradigm shift in the vegan bio-leather industry.

Our mission is to provide environmentally conscious manufacturers with an innovative, high-quality natural additive derived from an agricultural by-product.

EVERY M² OF ORGANIC NANOCARBO™ MEANS LESS SUFFERING FOR DEFENSELESS ANIMALS, LESS CO₂ THANKS TO A CLOSED AND ZERO-WASTE PRODUCTION CYCLE, AND MORE HOPE FOR THE PLANET.Please fill out the request form to receive our innovative plant-based material for your production, along with the full R&D ORGANIC NANOCARBO™ technical documentation for smooth integration into your process.

Please indicate the approximate quantity of plant-based booster you require.

Once we receive your request, our team will contact you to confirm the details and

provide the full R&D ORGANIC NANOCARBO™ technical documentation for smooth integration into your production.

Once we receive your request, our team will contact you to confirm the details and

provide the full R&D ORGANIC NANOCARBO™ technical documentation for smooth integration into your production.

We’d be happy to receive your contact information

you may have.

You can also reach us directly by phone or email.

Kyiv, Ukraine

📞 Phone: +38 (067) 942-24-23

📧 Email: vegan1booster@organic-nanocarbo.com

There are sustainable and ethical alternatives - and they're better for the planet!

By choosing them, we save animals, support local economies, and reduce our carbon footprint!